Let’s talk about nuclear.

Fossil fuel plants produce heat by burning coal, oil, or natural gas. These fuels can provide cheap electricity, but they also generate large amounts of carbon dioxide and other pollutants.

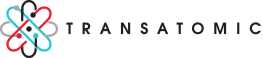

Nuclear reactors generate their heat via nuclear fission. This process unlocks vast amounts of energy from a small amount of fuel, and doesn’t generate carbon dioxide. In the core of the reactor there is a large, stable number of nuclear fission reactions, which occur when a uranium atom is struck by a neutron and splits in two, releasing additional neutrons and energy in the form of heat.

Fuel

Solid

![]()

Light water reactors are fueled by pellets of solid uranium oxide, supported within a thin metal framework. The metal cladding traps fission products, which ultimately stop the nuclear chain reaction. Furthermore, the metal cladding, and the solid fuel itself, are damaged by the radiation in the reactor core. The buildup of fission products and accumulation of damage limit the amount of time that uranium oxide fuel can remain in a light water reactor to about four years.

Fuel

Liquid

![]()

Molten salt reactors like Transatomic Power’s are fueled by uranium dissolved in a liquid salt. The fuel is not surrounded by cladding, making it possible to continuously remove the fission products that would otherwise stop the nuclear reaction. The liquid fuel is also much more resistant to structural damage from radiation than solid materials – simply, liquids have very little structure to be damaged. With proper filtration, liquid fuel can remain in a molten salt reactor for decades, allowing us to extract much more of its energy.

Light Water Reactors

—

Waste Production

10 tons/yr

Four years is not long enough to use up all the energy in the uranium fuel – light water reactors can use only about 4% of their available energy. This inefficiency leads to the production of approximately 10 tons of long-lived radioactive waste per year.

Molten Salt Reactors

—

Waste Production

4.8 tons/yr

Our reactor consumes nuclear fuel slowly and thoroughly, over the course of decades. Our extremely efficient fuel utilization means that we produce much less waste per year than a light water reactor, reducing the total volume of waste by over 50%.

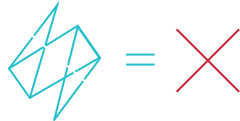

Light Water Reactors

—

Walk-away safe?

NO

Light water reactors require a continuous supply of external electric power to pump water over their core, to keep it from heating up catastrophically. The most advanced light water reactor designs can survive without electricity for up to 72 hours, but after this time, they require operator action to restore their electric power. Without this outside intervention, they would suffer fuel damage and, potentially, a meltdown.

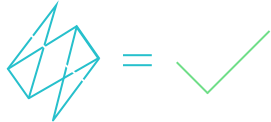

Molten Salt Reactors

—

Walk-away safe?

YES

Molten salt reactors have significantly different cooling requirements than light water reactors. They are therefore extremely safe, and do not require active cooling, even in the worst-case accident scenarios. At the bottom of their primary loop, they have a “freeze valve” – a plug of the same type of salt in the primary loop, only electrically cooled so that it remains solid. If the plant loses electric power, the freeze valve loses its cooling and melts. The salt from the reactor then drains into an auxiliary containment. In the auxiliary containment, the salt is no longer in a critical configuration, and thus is not producing as much heat. It gradually cools via natural convection and freezes solid over the course of a few hours. If our reactor loses all electric power during an accident, even if the operators are no longer on site, it will gradually coast to a safe stop.

Light Water Reactors

—

Operates at:

High

Pressure

Light water reactors operate at about 100 times atmospheric pressure. The high pressure is necessary to keep their water coolant liquid at their high operating temperatures. They also require the use of a large, expensive containment dome to hold this pressure in the case of an accident, and prevent the spread of radioactivity beyond the site boundary.

Molten Salt Reactors

—

Operates at:

Atmospheric Pressure

Molten salt remains liquid at atmospheric pressure, even at the very high temperatures present in a nuclear reactor. Since it is at atmospheric pressure, the design does not require a full containment dome, and in case of an accident, there is no pressure to act as a driving force to push radioactive material beyond the site boundary.

Let’s use the technology of today to better the future.

Graphite

![]()

Zirconium Hydride

FLiBe+UF4

![]()

LiF+UF4

33%-93%

![]()

5%

4 MWth/m3

![]()